We are providing the basis for a restful night’s sleep for our renowned customers from the furniture trade. The fibreglass-reinforced spring slats optimise every mattress and, with their elasticity adapted to the weight and body area, they ensure an optimal spine position when lying down.

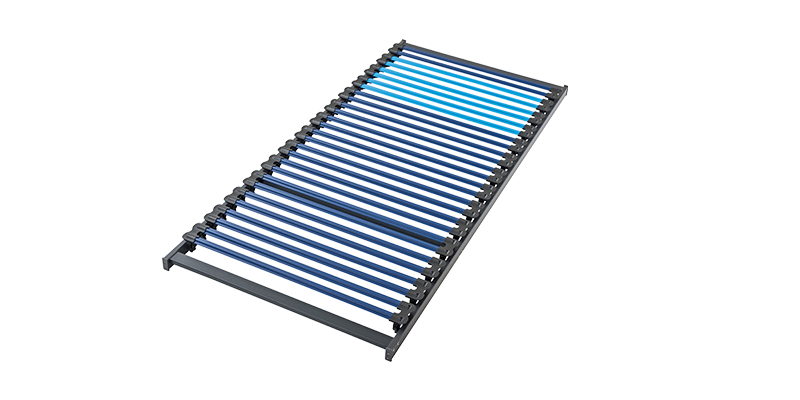

Our spring frames make turning over at night easier, thanks to a completely flat lying area. Interested? Then just keep on reading!

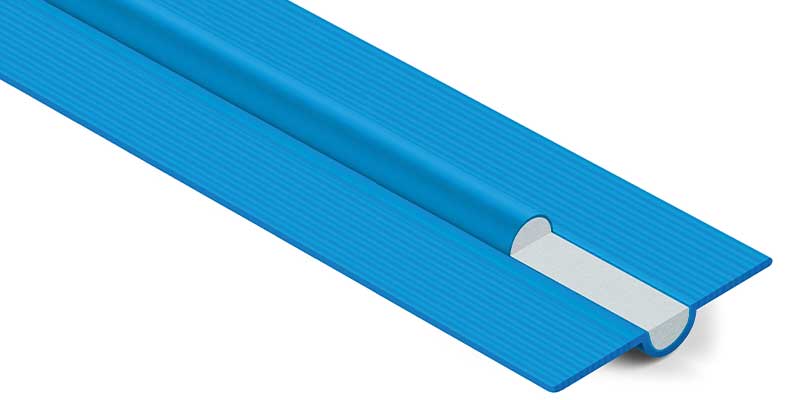

The slat technology follows research results on lightweight construction in the automotive industry. The fibreglass core is encased in a carrier material. Perflexion thus combines properties with Goodside technology that were previously considered incompatible: the slats are particularly light, flexible, extremely robust, long-lasting and hygienic all at the same time – and suitable for all types of mattresses.

We have said goodbye to traditional wooden slats because the flexible slats from Goodside impress with their durability, adaptability and the many ergonomic advantages. The materials guarantee consistent elasticity and prolonged durability exceeding by far that of wooden slats or springs. The fibreglass-reinforced plastic slats are available in different strengths, so everyone can set their preferred firmness through the slat arrangement. Tool-free and at home.

Based on our basic model, we adapt the number of slats, colours and branding so that the frames harmonise with the corporate design of the point of sale as well as the positioning.

MODULAR SYSTEM

Due to the number of glass fibres in the material, there are different levels of elasticity with the same external dimensions. Nevertheless, the colour code quickly tells you how firm a slat is. The different degrees of hardness and slat widths ensure optimally adapted ergonomics. The number of slats and their combination are freely selectable, although we recommend certain combinations from experience. The slats are available in various lengths and colours, also with markings. The caps can be fitted in seconds without tools and also offer exceptional suspension comfort.

GOODSIDE® does not have a segmental arch and can therefore also be foamed in directly or sewn into the cover. This saves material and reduces assembly time.

When the company was founded in 1948, Harald Schultz started his trade in mattresses and textile products. His son set new goals from the end of the 1990s and developed the company into an expert for slatted frames. In 2006, his son-in-law Christoph König took over. He focused on the research and development of new sleeping systems. An important milestone was the development of the first slatted frame system reinforced by fibreglass in 2009, which has been continuously optimised. With this project, Schultz Schlafkultur became a pioneer in the use of new materials for suspensions!

Since 2017, Schultz Schlafkultur has been part of the OKE Group from Hörstel.

Our unique slats and caps ensure cost savings through very simple assembly. Many system components can be mounted without tools, and even repositioning the slats of different firmness at home is easily done with many of our frames.

All products are developed at our headquarters and examined for ergonomics, elasticity and durability in our own test laboratory. Continuous controls also take place at material level. We guarantee quality and promise 25 years of the best spring comfort.

We supply major retail chains worldwide. Depending on the customer’s wishes, our slats are used for fixed and adjustable frames, for various frame widths and materials, and are also sometimes redesigned as special editions. We even offer electric and app-controlled adjustment mechanisms.